Digital QC

Scott Ward, principal officer of Southern Components and chair of SBCA’s Quality Control Committee, sat down with Kirk Grundahl to discuss the industry’s current in-plant quality control processes, along with SBCA’s Digital QC Program and how it is going to revolutionize the component manufacturing industry.

WHY SBCA DIGITAL QC

WHY SBCA DIGITAL QC

- Truss joints are being scrutinized more critically in the field

- CMs desire data to prove manufacturing performance

- QC accuracy evaluated anywhere in the construction process at any time

WHAT & HOW

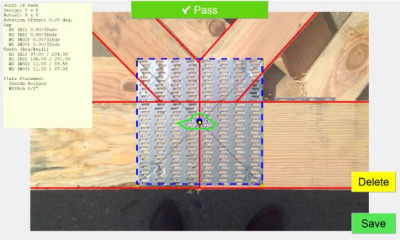

- Digital algorithms are quick, accurate & objective

- A small, rugged tablet, photographs & digitally inspects “Critical Joints”

- Takes 1/4 the time compared to traditional inspection

- Uses SBCA-unique-algorithms

- Limits human subjectivity & error

- Provides continuous improvement feedback loop

- Measure, compare, manage

MEASURE TO MANAGE – DO YOU IMMEDIATELY KNOW WHEN:

MEASURE TO MANAGE – DO YOU IMMEDIATELY KNOW WHEN:

- A machine is not pressing plates well; why?

- Crew #12 is having trouble with tooth roll; root cause?

- Certain joints are out of control; why?

- Crew #1 has three new team members & QC is affected; training?

ROOT CAUSE EVALUATION THEN SOLUTION

- Real-time data

- QC dashboard control charts & graphs lead to better decisions

- Create QC benchmarks for quick operation evaluations

VALUE TO COMPONENT MANUFACTURERS

- Synonymous with truss quality for:

- Truss Buyers

- Architects

- Engineers

- General Contractors

- Framers

- Building Officials

- Data helps show field issue causation

- Reduce jobsite quality disputes and backcharges

- Truss repairs do not have to be free