Another Weapon in Your Arsenal

Top chord-bearing trusses have several advantages building designers should know about

The more weapons you have in your arsenal, the easier it is to find a way to be a hero to your customer. One clear opportunity already in a component manufacturer’s (CM) arsenal is the top chord-bearing floor truss (TCB truss). The end condition of a TCB truss, where the top chord of the truss sits directly on the bearing location, provides several potential benefits.

The more weapons you have in your arsenal, the easier it is to find a way to be a hero to your customer. One clear opportunity already in a component manufacturer’s (CM) arsenal is the top chord-bearing floor truss (TCB truss). The end condition of a TCB truss, where the top chord of the truss sits directly on the bearing location, provides several potential benefits.

The TCB truss provides greater flexibility to the building designer when it comes to a building’s elevations. With a TCB truss, floor truss depths can be increased for greater spans or greater stiffness without increasing the height of the floor. In addition, if needed, overall building heights can more easily be minimized with TCB trusses by adjusting wall heights rather than floor depths.

Having TCB trusses in a multi-story building also eliminates the need for rim board on the exterior of the buildings. Rim board can periodically be hard to source, takes significant time to install, and is typically expensive (see sidebar). In addition, because it is often made from engineered wood products that can be more susceptible to weatherization during construction it can create unintended installation challenges.

TCB trusses can also be beneficial when there are mid-bearing conditions, because it allows the girder or beam to be incorporated into the floor dimension. This eliminates the necessity for drop beams and allows the building designer to preserve a consistent ceiling height. Alternately, TCB trusses can eliminate the need for expensive hangers when tying trusses into a beam or end wall. The ability to incorporate beams into the floor dimension can also be beneficial when it comes to rough opening headers in exterior walls. For instance, TCB trusses can be designed to allow a window rough opening height to extend all the way to the ceiling height.

On a recent 175,000 square-foot multi-family project, the developer was approached by the component manufacturer and its plate supplier about switching out bottom-chord bearing trusses for TCB trusses and removing all the two-ply LVL band board specified throughout the project. The project was five stories, so that meant eliminating tens of thousands of lineal feet of LVL throughout the project and simply increasing the height of the exterior walls. While the wall stud material cost increased as a result, switching to TCB trusses saved the developer over $200,000 on the cost of framing materials and labor. It was an easy way for the CM to become the hero!

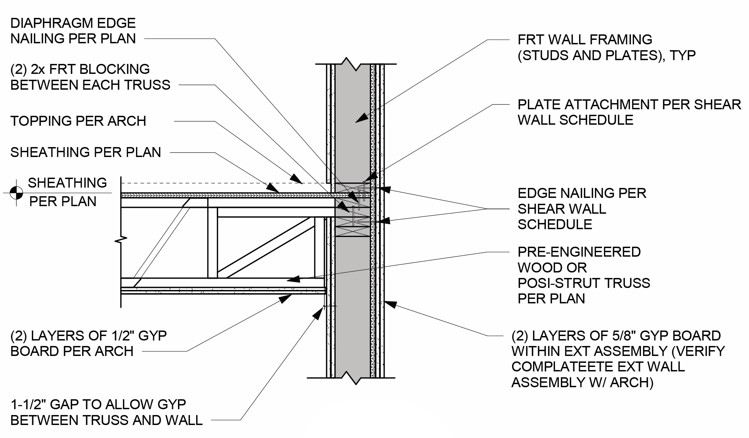

Another area in which TCB trusses shine is in Type III-A buildings, which require a two-hour rated exterior wall assembly. In this application, the bottom chord of TCB trusses can be recessed back to more easily accommodate gypsum that is applied all the way up the exterior wall. This approach makes both installation and field inspection of the assembly easier.

TCB trusses also improve the installation process for framers. Whether it’s removing exterior band board or blocking, eliminating interior beam hangers, or improving exterior wall fire-rated assemblies. Not only is there less material to install, but there are also less opportunities for error. This adds clarity to the jobsite framing schedule, while also simplifying the plan check and inspection process, which is a win for everyone on the project.

TCB trusses also improve the installation process for framers. Whether it’s removing exterior band board or blocking, eliminating interior beam hangers, or improving exterior wall fire-rated assemblies. Not only is there less material to install, but there are also less opportunities for error. This adds clarity to the jobsite framing schedule, while also simplifying the plan check and inspection process, which is a win for everyone on the project.

TCB trusses may not be the best solution on every project, but their capabilities provide unique solutions for building designers to address several structural and performance challenges. The building designers you work with should be aware that they are a powerful alternative and should be considered in their plans.

This article is the result of a collaboration between the members of the Truss Plate Institute’s Technical Advisory Committee (TPITAC) and SBCA. It is part of a technical article series driven by TPITAC members that seeks to address pertinent engineering topics and provide design best practices.

Sean D. Shields, Director of Marketing