Helmets vs. Hard Hats

Helmets vs. Hard Hats

Rethinking Head Protection on the Jobsite

Walk onto any construction site across North America, and you’ll likely spot a sea of hard hats— those familiar, domed plastic shells that have been synonymous with worker safety for over half a century. But look closer and you may notice something new: sleek, low-profile helmets, often equipped with chin straps, better ventilation, and a more modern look.

These are construction helmets, and they’re part of a growing shift in the world of jobsite safety. While hard hats remain the standard, construction helmets are fast becoming the new frontier in protecting workers from all types of head injuries and falls. Many General Contractors are adopting policies requiring them on their projects moving forward.

But what exactly separates a helmet from a traditional hard hat? And should your crew be making the switch? At Ace Carpentry, Inc., we did, but not all at once. After we understood the added safety benefits, we approached the decision deliberately, taking time to learn from our general contractor partners, research available options, and evaluate what would work best for our crews and job types.

A Brief History of the Hard Hat

The classic hard hat traces its roots back to the early 20th century. Inspired by military helmets used during World War I, early models were made of steamed canvas, glue, and black paint. By the 1950s, they evolved into thermoplastic or fiberglass designs that were lightweight, durable, and relatively affordable.

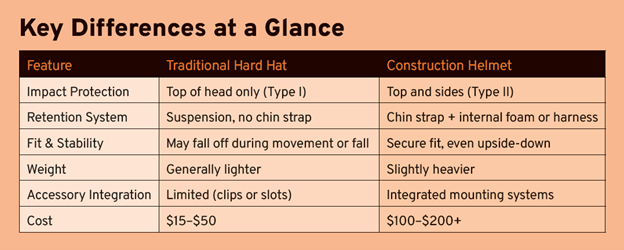

These traditional hard hats (like the familiar Type I, Class C and E models in the U.S.) are designed primarily to protect against impacts to the top of the head, such as falling tools or debris. For decades, they’ve served that purpose well. But they’re not without limitations.

Enter the Helmet: A Modern Take on Safety

Unlike hard hats, construction helmets are modeled after those used in climbing, rescue operations, and military contexts. They offer 360-degree head protection, including lateral impact resistance, and come equipped with chin straps to stay securely fastened—an essential feature for workers at height.

Helmets are made of advanced materials like ABS (Acrylonitrile Butadiene Styrene) or polycarbonate, and often feature:

• Foam liners for impact absorption (similar to bicycle or sports helmets)

• Ventilation systems

• Accessory mounts for lights, visors, hearing protection, and more. With these options attached to the helmets, the workers no longer have to carry them separately.

• Full-brim or short-brim designs

• Custom fit systems like adjustable ratchets and padding

• Customizations with logos and colors similar to traditional hard hats

This modern design provides not just better protection, but also enhanced comfort and usability, a key factor in compliance.

Seeing these features on paper is one thing; understanding how they perform in the field is another. At Ace, we brought in multiple helmet models across different brands and price points and tested them on active jobsites. Our field teams were involved from the start, providing honest feedback on comfort, ventilation, usability, and overall fit. That input helped guide our final decision and ensured the helmets we selected worked for the people actually wearing them every day.

Why the Shift?

The Safety Argument The construction industry has long been plagued by head injuries. According to OSHA, traumatic brain injuries (TBIs) are one of the leading causes of death in construction. Falls, slips, and being struck by objects remain common contributors.

A standard hard hat can fall off during a fall or when a worker bends over, especially if not worn with a chin strap. This can not only put the worker wearing it in jeopardy but also create a falling object from overhead to another worker below, if on a leading edge. Worse, it provides minimal side protection, despite the fact that many head injuries occur from side or oblique impacts, not just from objects falling straight down.

This is where helmets shine.

One pivotal moment in the industry’s attitude toward helmets came in the late teens and early twenties, when many large general contractors in the United States began testing safety helmets on their sites. Soon after, many companies followed suit. In January 2025, CBG implemented the policy as well.

“CBG Building Company transitioned to safety helmets for our employees in 2024 and for all subcontractor trade partners a year ago. We updated our safety program to reduce the risk of head injuries and traumatic brain injuries (TBI) across our workforce,” says Dan Blankfeld, Vice President of Safety at CBG Building Company. “We want our partners and employees to be protected by the most modern and effective equipment available. Traditional hard hat designs are over 50 years old and provide limited protection from lateral strikes or falls. In contrast, modern construction helmets are purpose-built for these risks and have demonstrated a significant decrease in head injuries.”

‘’Traditional hard hat designs are over 50 years old and provide limited protection from lateral strikes or fall.''

In December of 2023, the U.S. Department of Labor's Occupational Safety and Health Administration (OSHA) announced that it is replacing traditional hard hats used by its employees with more modern safety helmets to protect them better when they are on inspection sites.

Adoption Challenges: Cost, Culture, and Comfort

Adoption Challenges: Cost, Culture, and Comfort

Despite the safety benefits, the transition isn’t without friction.

1. Cost: A standard hard hat might cost under $30. A quality helmet? Easily $100 or more. For large crews, this adds up fast.

2. Acceptance: Many veteran workers resist change. Helmets can feel “overbuilt,” especially for those not working at height. Appearance may also create pushback.

3. Regulatory Lag: In the U.S., OSHA doesn’t yet require helmets or mandate side-impact protection. ANSI standards (Z89.1) still separate Type I and Type II protections, and most hard hats remain Type I.

We experienced many of these challenges firsthand. Cost was a consideration, especially when equipping large crews, and there was an adjustment period as our teams got used to the new fit, feel, appearance, and chin strap. Like most changes on a jobsite, it took some time. Today, however, helmets are simply part of everyday life at Ace. What once felt different is now routine—and that experience mirrors what many companies are beginning to see as they evaluate risk and long-term safety outcomes.

As more companies conduct internal risk assessments and track injury data, the cost-benefit equation is starting to shift.

What the Standards Say

In the U.S., head protection is governed by ANSI, which classifies helmets based on:

• Type I: Protects from top impact (typical hard hats)

• Type II: Protects from top and lateral/side impact (typical construction helmets)

Additionally, helmets and hard hats are rated by class:

• Class G (General):

Tested at 2,200 volts

• Class E (Electrical):

Tested at 20,000 volts

• Class C (Conductive):

No electrical protection, often better ventilation

Most construction helmets meet Type II, Class C or Class E standards, making them suitable for general use or electrical work, respectively.

The Bottom Line: Should You Switch?

If your team works at height, around moving equipment, or in environments where side impacts are likely, helmets can offer superior protection and peace of mind. While the upfront cost is higher, the long-term benefit of reducing lost-time injuries, insurance claims, and fatalities is compelling.

Moreover, younger workers and safety-minded organizations are increasingly embracing helmets as the new norm. Just as seat belts and safety glasses were once debated, helmets are likely to become standard—sooner than later.

Recommendations for Safety Managers

1. Conduct a Job Hazard Analysis (JHA): Evaluate where lateral impacts, falls, or head trauma are likely.

2. Trial Helmets with Small Crews: At Ace, we took a “test drive before we buy” approach, starting with higher-risk environments and smaller crews. Testing multiple manufacturers and models allowed us to compare comfort and features while gathering real feedback from our field teams before rolling out the helmets company-wide.

3. Choose Helmets That Meet ANSI Type II Standards: Ensure compatibility with necessary accessories.

4. Educate & Communicate: Emphasize the why, not just the what. Personal stories and data can help win over skeptical workers.

There are numerous educational resources and organizations available, including but not limited to the following:

• Hard Hats to Helmets: hardhatstohelmets.org

• OSHA Bulletin: osha.gov/sites/default/files/publications/safetyhelmet_shib.pdf

• National Association of Home Builders (NAHB): nahb.org/blog/2025/07/safety-helmets-jsi-study

• Job-Site Safety Institute (JSI): jssafety.org/downloads/ JSI-Safety-Helmets-Report.pdf

5. Plan for Budget Impact: Look for bulk discounts or pilot programs from vendors. Manufacturers are continuing to improve the products and pricing as more options come on the market.

6. Identify the Date for Transition: Agree with your General Contractor on the date for implementation. It should not occur in the middle of the job where a subcontractor does not have the opportunity to potentially build the costs into the project budget. Instead, starting it on your next upcoming project allows others to plan accordingly.

Conclusion

The hard hat has served the construction industry well for nearly a century. But as jobsite risks evolve and safety technologies advance in personal protective equipment (PPE), the traditional hard hat may no longer be enough.

From our experience at Ace, when the transition is approached collaboratively and thoughtfully, helmets become less about change and more about simply doing the work safely.

Construction helmets represent the next generation of head protection—one that could prevent life-altering injuries and save lives. While change never comes easy, the safety and security of workers is worth the investment and effort to change.