Leveling-up Operations in Your Plant

Quality Bootcamps are a Huge Success

By Molly E. Butz

In 2024, SBCA staff began planning to bring to life a series of free regional Quality Bootcamps in 2025. The goal was to create a back-to-the-basics curriculum to drive home the importance of quality management in a component manufacturing facility. Available at no charge for both members and non-members alike, these Quality Bootcamps are intended to set a foundation for attendees to return to their facilities to build and enhance their comprehensive quality management programs. Now, as Q3 comes to a close, more than 160 people have registered to attend SBCA’s Quality Bootcamps in 2025, and there are still two more events on the calendar before the end of the year.

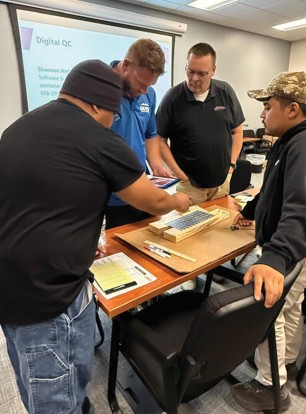

At any one of these events, you’ll find SBCA Technical Director, Greg Greenlee, P.E., or Managing Director, Molly Butz, presenting the two-day program that includes both classroom learning and hands-on activities. The classroom curriculum covers a wide range of topics including a deep dive into ANSI/TPI 1 Chapter 3, quality requirements of model building codes, understanding the differences between quality control manuals, inspections, and quality assurance, data management, and more. In contrast, the various hands-on activities drive home a better understanding of what a thorough QC inspection should entail and provide a foundation of understanding for how the SBCA Digital QC software is making that process more efficient and effective.

So far, the Quality Bootcamps have been very well-received with a lot of positive feedback. Brian Schultz, of Timberline Truss, was excited about the technical information he received at the first bootcamp in Phoenix, AZ, saying, “I really appreciated gaining a better understanding of the expectations in the [building] code (both clear and gray), and second, gaining the hands-on experience of doing an inspection with others beside me who have a lot of field inspection experience.”

So far, the Quality Bootcamps have been very well-received with a lot of positive feedback. Brian Schultz, of Timberline Truss, was excited about the technical information he received at the first bootcamp in Phoenix, AZ, saying, “I really appreciated gaining a better understanding of the expectations in the [building] code (both clear and gray), and second, gaining the hands-on experience of doing an inspection with others beside me who have a lot of field inspection experience.”

Attendees also consistently express that they have learned things they can take back to and implement immediately in their facilities. “It was great to get some tips and tricks I hadn’t realized, like that I can take a photo with just my phone’s camera and send it later to the tablet to work on an inspection,” says Brice Matthews of Shelter Systems, an attendee at the Jessup, MD Quality Bootcamp. “I also learned I can still go through with an inspection even when our internet drops off.”

Quality assurance audits are an important part of a component manufacturers’ quality management program, and the bootcamps provide the education attendees need to actively participate in their third-party quality assurance audits in a way that will have long-term benefits for their manufacturing facility. It’s easy to confuse quality control and quality assurance if you haven’t taken the time to sit down and truly understand the difference. But we really try to make it clear in our training, so that when the attendees leave the two-day event, not only can they differentiate between the two, they can also go back to their teams and teach others.

“The objective of the bootcamp is to raise awareness of the quality requirements and provide CMs opportunities to improve their manufacturing quality,” says Greg Greenlee, P.E. “The course targets a wide variety of roles at the plant including QC inspectors, QC managers, and plant managers. We’ve even had some truss technicians and managers attend.” The varied group of attendees provides a great deal of insight for everyone in the room and, for those new to quality control and quality assurance, having folks with more experience provides a truly robust learning opportunity.

SBCA’s family of quality-focused products and services makes leveling up quality control and quality assurance in your component manufacturing easy to access, and the new Bootcamp series makes implementing all these strategies easier by providing a solid foundation in just two days. “SBCA takes in-plant quality control and quality assurance very seriously,” says Greg Greenlee, P.E., “And the bootcamps take the guesswork out of putting both things to work in your manufacturing facility.”

Registration for upcoming Bootcamps can be found on the SBCA website at www.sbcacomponents.com/quality-bootcamps.

SBCA plans to continue the Quality Bootcamps in 2026 with seven new locations and dates:

Region 6: Jacksonville, FL

January 12-13, 2026

Region 6: Fort Lauderdale, FL

January 15-16, 2026

Region 2: Riverside, CA

March 10-11, 2026

Region 5: Columbus, OH

May 12-13, 2026

Region 2: Salt Lake City, UT

July 14-15, 2026

Region 1: Kent, WA

August 18-19, 2026

Region 6: Atlanta, GA

October 20-21, 2026