Roof Trusses Open Door to Broader Structural Solutions

Originally Published by: LBM Journal — June 4, 2025

SBCA appreciates your input; please email us if you have any comments or corrections to this article.

By Mike Berger, LBM Journal

Far from being something new, it may surprise you to learn that component construction has been around for thousands of years. For example, the ancient Celtic people utilized components to build Stonehenge in England. The oldest parts of the structure were built from 3000 to 2935 BCE, and rather than being shaped onsite, the very large, upright sarsen stones that make up the bulk of the structure were quarried offsite in the Marlborough Downs more than 20 miles away from the actual build site. These exceptionally heavy stones—some weighing over 25 tons—were then transported to the build site and erected there in place.

In today’s construction world, component construction represents an efficient way to increase accuracy of construction while helping to deal with a diminished workforce. As defined by the Structural Building Components Association (SBCA), structural building components are roof trusses, floor trusses, and wall panels that are custom designed and built in specialized manufacturing environments. Components are delivered to the jobsite where framers install them along with permanent bracing to create the overall structural system. Structural building components should not be confused with factory-built modular or mobile home construction, although components can certainly be used in those particular applications.

Component construction exists in two distinct forms. In one form, the LBM dealer has made the investment to build their own truss plant, while in the other, the LBM dealer sources their components from an independent component supplier. Unfortunately, for many LBM dealers, there persists misconceptions as to what component construction is, no matter which path is followed.

For example, industry leaders point out that a component business is not technically the same as a LBM operation. Rather than simply supplying building materials, the LBM dealer serves more as a manufacturer. “The financials need to be different and have a different approach,” says Jess Lohse, executive director of the SBCA. “Now, the customer base is the same. A lot of the suppliers can be the same. The material is similar enough. But just having that understanding that it is different, they need to have a different business strategy, because I’ve seen some that will apply what worked in an LBM operation, but when that’s applied to components, that’s asking for probably more disruption than what they’re ready to handle.”

As well, there exists a knowledge gap when it comes to the value prospect of components. “I think that there’s a lack of a clear understanding of just what value is able to be added when the use of off-site labor and off-site components is brought onto a project, points out Stephen Keller, director of design engagements for MiTek, a global company that provides integrated software, services, engineered products, and automated solutions for the building industry. Speed of construction is just one benefit, he says. “Trusses are able to be erected a lot faster than traditional construction, but a lot of the expertise that used to be around with that 30-year framer who knows exactly how to cut, snap and install rafters just isn’t there. And so taking that expertise in design and the manufacturing and embedding it into the software and the automation helps the project and therefore the clients be a lot more efficient and profitable. It’s a great way for LBM dealers to look at adding more to their markets and helping their customers.”

Scott Sanders, building materials sales leader for Preston Feather Building Centers and Design Showrooms, echoes similar thoughts regarding the understanding of value. “There is reluctance, because some of the guys that υ have been framing for years still think that they can build it faster, or they’re relying on their ability to build a better wall than what they think is going to come out of the panel manufacturing plant, but once someone gets a taste of it, they’re finding out that it can be a good experience. I think it’s even more that they don’t understand how the math works out. We had a couple of customers that we talked to recently who thought that their profit margins would erode because they don’t have their crews out there building walls; they’re just setting panels, right? So more of the cost is built into the manufacturing of the panels versus the labor of their crew building the wall. We show them how the math works, especially if you’re able to build the house faster, you can actually be shortening your build cycles and getting more built in every single year.”

Benefits of components

Despite these misconceptions, experts say, the benefits of component construction are many, especially in this world of diminished workforces and lack of experienced labor.

Despite these misconceptions, experts say, the benefits of component construction are many, especially in this world of diminished workforces and lack of experienced labor.

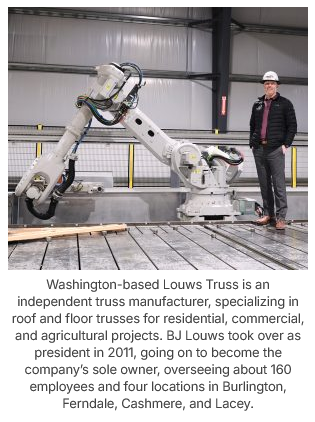

Speed to market is a big benefit, says John “BJ” Louws, president of Louws Truss Inc. “There was a player in our market who was framing houses in a matter of days,” he explains. “They would get their first floor and floor trusses dropped in the morning, and they would get that laid down and sheeted that afternoon, they would get the first four walls the next morning, they would get the second floor that afternoon, then the second floor walls. And the morning of the third day, they would get their roof trusses and be fully framed in three days, on a single-family two-story house. And that’s kind of the potential of this off-site componentized way to build.”

Another area where the speed of components is a benefit is in markets that are weather-vulnerable. “We’ve seen components done really successfully, and I think especially in our markets, with weather and other variables such as labor that are challenges,” says Rachel Huntman, president of Preston Feather Building Centers and Design Showrooms. “Being able to use components to button up the house quickly before weather sets in, especially is a big deal for us. Just because you have a really complex or intricate custom build doesn’t mean you can’t use panels. So that’s been something that we’ve found a lot of success with, actually having or introducing our builders to the panel designer, having them see other builders using the panels successfully, has been really helpful for us.”

Along with speed of assembly, accuracy is another strong point for component construction. “The accuracy of the material quote that the LBM dealer can offer via the component software can really narrow the discrepancy and make them much more competitive and accurate,” says SBCA’s Lohse. “There’s still going to be discrepancy there. But I’ve done projects where you see the difference, the same set of plans, different takeoffs, how the variation narrowing that is an opportunity, and providing that service and just being kind of that vendor of choice for the customer.”

“It takes a lot of the guesswork away from the framer when they’re 20 or 30 feet in the air, where they’re literally making engineering decisions,” Lohse continues. “Components take all of that and moves it further ahead in the supply chain with the manufactured component.”

One other benefit of component construction that should not be discounted is its ability to serve as a recruiting tool for the LBM dealer. “So as we know, labor is getting harder to come by,” explains MiTek’s Keller. “There isn’t as much of a desire for the new generation to pick up a saw or work out in the field, but there is desire from that new workforce to work more with computers and automation. And so that does make it a desire for high school students or the individual from a technical college to look at working with a LBM dealer to have a future as an automation expert or something like that, to help them expand. We’re moving that expertise away from the field and into an off-site environment.”

Differentiate to succeed

Considering the numerous benefits components bring to the market, there are ways these benefits can be used by LBM dealers to differentiate themselves from their competition and create “sticky” customers in the process.

Considering the numerous benefits components bring to the market, there are ways these benefits can be used by LBM dealers to differentiate themselves from their competition and create “sticky” customers in the process.

“I think one of the best ways that LBM dealers can set themselves apart is by utilizing the component construction software as a visual aid,” explains MiTek’s Keller. “Show your customers how they can build better, how they can be more efficient, how utilizing the experience of not just the builder, the carpenter, or the utility trades, but bringing them all into the right environment with the truss design software, and helping them design the building as a system versus individual silos, is more efficient.”

It’s not just the big things that matter. Attention to the smaller details of component construction can help differentiate the LBM dealer. “Just do something a little bit more to help out everybody downstream,” says SBCA’s Lohse. “So the walls are an opportunity, but that’s going to be one of the easiest things for the people on site to build, too. They’re not υ going to want to give away part of their pie. That’s where the value comes in. And this is where I think LBM dealers might have an easy opportunity to add value, such as with drilling the holes for the electrical wire to go through.”

“I think that’s another opportunity for components, is taking it a step further, to where some of the mechanicals could be pre-installed,” Lohse opines. “Like with the staircase—cutting stairs is one of the most difficult things that you can do on a jobsite. If you can bring in the computerization in this cutting, manufacture that off site, and then deliver it to the jobsite and drop it in, that’s another huge opportunity for anybody in the component industry or the LBM operation, because that is such a difficult skill set to replicate on the job.”

Be willing to look at every project as an opportunity for components, recommends Preston Feather’s Sanders. “Many of our competitors offer panels, but it’s just the projects they feel are able to be analyzed. I think that’s the difference. Preston Feather is very open to the fact that pretty much any project you look at could be panelized. Our competitors don’t think that way, and they’re thinking that just maybe multi-family or just certain styles of projects can be panelized. But I think that’s what differentiates us a little bit more, is that we will take any drawing to our partner and have him review it. He looks at the design and tells us, is this worth it or not? And we advise our builders accordingly.”

Best practices

In order to achieve that differentiation, component construction experts and fellow LBM dealers recommend a few best practices for success. For the LBM dealer who may be thinking of establishing their own truss or component plant, MiTek’s Keller encourages them to talk to their peers, especially those that have been down this journey before. What has their experience been? How have customers reacted to it? “I would encourage them to talk to their own customer base,” he adds. “If they’re able to discuss the value of components, and highlight what a difference it could make, or has made, with other clients, they might start to see their customers changing their minds, which means that there’s a better opportunity in the market for them to have that conversation about moving forward with their own evolution as well.”

In order to achieve that differentiation, component construction experts and fellow LBM dealers recommend a few best practices for success. For the LBM dealer who may be thinking of establishing their own truss or component plant, MiTek’s Keller encourages them to talk to their peers, especially those that have been down this journey before. What has their experience been? How have customers reacted to it? “I would encourage them to talk to their own customer base,” he adds. “If they’re able to discuss the value of components, and highlight what a difference it could make, or has made, with other clients, they might start to see their customers changing their minds, which means that there’s a better opportunity in the market for them to have that conversation about moving forward with their own evolution as well.”

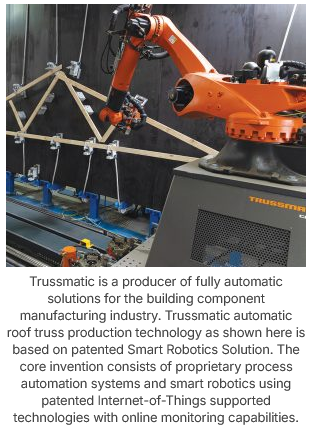

Matti Lehtipuu, founder and board member of Trussmatic, a producer of fully automatic solutions for the building component manufacturing industry, recommends investing in the best technology possible. “Don’t start with old technology, as it’s going to be outdated fairly soon,” he says. “Go with the latest technology so that you have a competitive advantage when you enter the market. But at the same time, like any new business, you need to do your homework, and you need to work on your business plan.”

SBCA’s Lohse recommends taking advantage of existing resources such as the SBCA. “Attend events or surround yourself with other component manufacturers, either locally, regionally or nationally, at an event, where you can ask the questions, ask what people wish they would have done otherwise. Go on a fact-finding mission, and understand how many different ways there are to do these things. Talk with as many people as you can, is really the first goal, and then really understand every option that’s available. What are all the options? How automated do you want to get? Do you want to just be able to produce trusses? Or do you want to make it to where you minimize labor? Obviously, that comes with investment, and then make sure that you can work through it and pencil out the ROI to determine if it’s a good business decision.”

For those that are looking to begin or expand component construction offerings with an existing component supplier, Preston Feather’s Huntman stresses communication both with the vendor and the end user. “I think it goes back to creating that relationship with that particular panel vendor and asking them what they are offering, as far as options. Having that ability with a panel manufacturer goes a long, long way, especially on products specifying premium materials. I think on the other side of it is the relationship with the builder who is going to use those products. Just because you can buy panels doesn’t mean that you can install them the right way, and we’ve seen it done the wrong way before, and that can really slow down the project. So I think making sure that they’re really aware of what it takes, and making sure that you do your work on the front end, making sure that they’re really prepared for it is a big deal, because when it does go right, you’ll have somebody who’s really committed to using panels in the future. But if it goes wrong, it can be very costly.”

To help things go as well as possible, Shane Soule, president of ProTec Panel and Truss recommends hiring a specialist. “Everyone should consider hiring a truss rep that manages all of the trusses, even if they don’t build them, that has the knowledge and can do the field visits, that sort of thing, and not have to rely on the vendor, because I see it all the time: for LBM dealers that two step, it’s a challenge and a very long uphill battle to take a LBM sales rep that knows how to sell sticks, siding, and trim, and then have them have a very strong knowledge of truss packages. This doesn’t work. It’s a completely different thing. So if you can, invest in someone that has component knowledge, that can represent things, and can even help shop the two step truss company.”

Looking into the future

Considering market factors such as diminished labor forces and the lack of that old knowledge base that came from veteran framers, it seems likely that the use of component construction will be on the rise, and the smart LBM dealer will be the one exploring how to best take advantage of this trend.

Considering market factors such as diminished labor forces and the lack of that old knowledge base that came from veteran framers, it seems likely that the use of component construction will be on the rise, and the smart LBM dealer will be the one exploring how to best take advantage of this trend.

As MiTek’s Keller explains, “It’s worth noting that over the last five years, there’s been increased desire for architects, engineers, contractors, to engage their component manufacturers earlier on in the design process, to lean on 3D modeling and those design tools, and leverage the experience of that truss manufacturer or LBM dealer. And so by opening up yourself to expanding your operations and offering trusses as well, you might also gain a seat at that table earlier on, to be that problem solver for your clients.”

LBM dealers who have already embraced component construction understand the benefits, and also see it as a growing trend. “I think there will certainly be a tipping point for the industry to understand the value in it,” Preston Feather’s Sanders points out. “There are so many who historically have not used components, and trust their methods. But as soon as you have somebody believing in this process, they’re not going to look back. There are so many benefits. The cost of what you’re doing is a big piece of it, but the time savings, and the fact that your labor market in this industry is not going to be increasing in the long run is a huge factor. So it’s a forward thinking move for many builders who are going that route.”

Whether an LBM dealer chooses to invest in establishing their own component/truss operation or instead takes the two-step process, it seems clear that component construction will continue to gain ground, and the competitive LBM dealer needs to be prepared. As ProTec’s Soule puts it, “I think that’s the challenge for everyone; there’s a lot of money being spent out there by the nationals to create these systems, and if you don’t have them, then you really can’t compete if you cannot offer that piece of it. So not to be doom and gloom, but if you are like, Hey, these are on the rise and people are doing these things, it’s not out of the realm for your yard to do a little bit of research into that, because it’s not a huge investment to have that offering.”