Top Tier Enhancements

A look at top chord-bearing truss design provision enhancements in ANSI/TPI 1-2022

Thanks to significant improvements in the latest update cycle of the ANSI/TPI 1-2022 standard to enhance the design provisions for top chord-bearing trusses, they are going to become even more attractive to builders and building designers. These changes have the potential to make top chord-bearing trusses even more cost-effective and expand their applicability in floor and roof construction.

Thanks to significant improvements in the latest update cycle of the ANSI/TPI 1-2022 standard to enhance the design provisions for top chord-bearing trusses, they are going to become even more attractive to builders and building designers. These changes have the potential to make top chord-bearing trusses even more cost-effective and expand their applicability in floor and roof construction.

Traditional Design Methodology

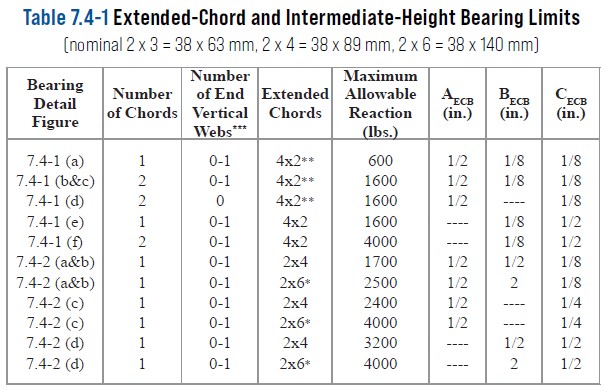

In previous editions of the TPI 1 standard, the design provisions for top chord-bearing trusses were limited to a prescriptive table (see Table 7.4.1) that specified maximum allowable reactions. This table was developed based on testing conducted by TPI member companies and others in the 1980s of top chord-bearing parallel chord trusses in limited configurations. The table provided a reliable design solution for a range of specific top chord-bearing configurations.

The prescriptive table has served the truss industry well since its initial publication in 1987 supplements to the TPI design specifications, offering designers a quick and convenient method for designing top chord-bearing trusses, and remains an option within the 2022 edition. However, it presents certain limitations, including:

- A maximum ½-inch gap between the edge of bearing and the vertical web

- The connector plate at the extended chord joint had to be located in a prescribed location without allowance for normal plate positioning tolerances

- No variation in strength was recognized for

different species/grade

of lumber - The design of the connector plate at the top-chord joint was not addressed

- No consideration or benefit was given for using lumber sizes larger than 2x6 (e.g. 2x8 versus 2x6 on flat trusses)

* or greater, ** 3x2 Extended Chords shall be permitted with maximum allowable reactions of: 430 lbs. for detail 7.4-1(a), 1150 lbs. for details 7.4-1(b), 7.4-1(c), and 7.4-1(d), ***End vertical Web is limited to 1.5-in. (25 mm) depth in 4x2 (or 3x2) Trusses and 3.5 -in. (89 mm) depth in 2x Trusses.

* or greater, ** 3x2 Extended Chords shall be permitted with maximum allowable reactions of: 430 lbs. for detail 7.4-1(a), 1150 lbs. for details 7.4-1(b), 7.4-1(c), and 7.4-1(d), ***End vertical Web is limited to 1.5-in. (25 mm) depth in 4x2 (or 3x2) Trusses and 3.5 -in. (89 mm) depth in 2x Trusses.

Design Methodology Changes in TPI 1-2022

Instead of only relying on prescriptive design methodology, the TPI 1 standard now includes a more advanced and comprehensive analytical design methodology.

This new approach allows for the consideration of any extended-chord-bearing condition, whether it is the top or bottom chord. The analytical-based design also takes into account various crucial factors, such as:

- The size of the lumber used in the truss

- The species and grade of the lumber

The distance between the edge of the bearing and the first vertical web - The placement and size of the connector plate

- The absence of wane in the chord extension

By incorporating these elements into the truss design methodology, this approach not only enhances the accuracy of the final truss design but also allows for greater flexibility and adaptability to different construction scenarios.

Designing For Failure Modes

The determination of the maximum allowable reaction for an extended-chord-

bearing truss in the latest edition of ANSI/TPI 1-2022 considers the following failure modes (TPI 1 sections added for reference):

- Compression Perpendicular to Grain (7.3.13.1) - This check is crucial in preventing the crushing of the chord extension under the design load. This crushing is usually considered a serviceability issue, but it can also be a structural safety issue, as it can trigger other failure modes of the plate and chord as the crushing causes the wood section to break down. The presence of wane in the chord extension significantly affects this check, which led to the inclusion of the Wane Factor (Cwane) in the TPI 1 standard. By strictly prohibiting wane in the extended chord region (i.e., Cwane = 1.0), a substantial increase in bearing capacity can be achieved (refer to Figure 1).

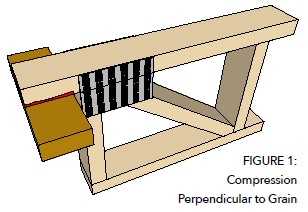

- Shear in the Chord Extension (7.3.13.3) – This design provision ensures that the extended chord does not exceed the allowable horizontal shear stress (Fv) and recognizes increased material capacity with smaller wood volume exposed to shear. In simpler terms, it guarantees that the lumber does not fail in a horizontal plane through the center of the chord (visualize bending a deck of cards and how the individual cards slide over each other; this scenario is analogous to a horizontal shear failure in lumber (refer to Figure 2)).

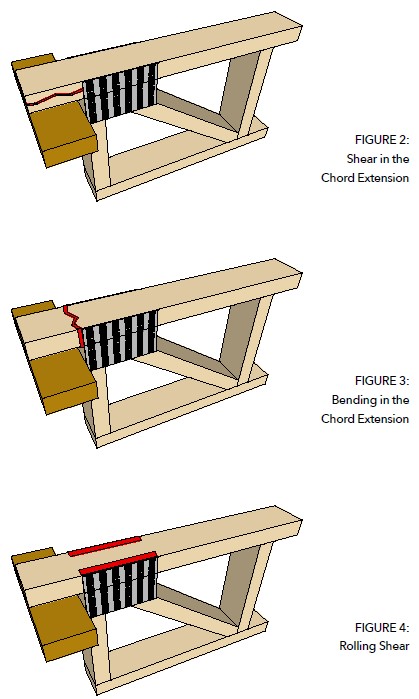

- Bending in the Chord Extension (7.3.13.2) – This design provision ensures that the extended chord does not exceed the allowable bending stress (Fb). This check, among others, becomes critical when the gap between the edge of the bearing and the first vertical web exceeds ½ inch (refer to Figure 3).

- Rolling Shear (7.3.13.4) – This check focuses on the plate-to-lumber connection and ensures that the forces in the extended-chord joint do not surpass the rolling shear capacity. A rolling shear failure occurs when the wood fractures around the connector plate and chunks out a section of the lumber with the teeth remaining embedded, as opposed to the typical tooth holding failure where the plate teeth pull out of the lumber (refer to Figure 4). This failure mode is not a common failure mode for wood trusses, but it can occur with the large perpendicular-to-grain force typical in top chord-bearing joints. It had not previously been considered by the TPI 1 standard but was able to be addressed by recent research and testing.

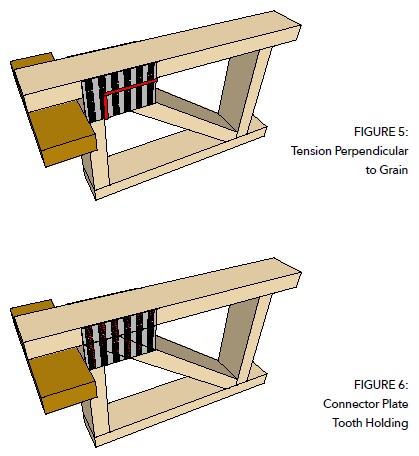

- Tension Perpendicular to Grain Tension perpendicular to grain (7.3.13.5) – This design provision ensures the chord does not fracture through its thickness at the edge of the connector plate. This check becomes more critical on extended-chord-bearings as the plate bite into the chord decreases relative to the chord depth.

- Connector Plate Tooth Holding (Lateral Resistance) (8.3.2.3) – Similar to the check performed on all other joints on a truss, this check ensures that the connector plate possesses sufficient tooth holding capacity to withstand the forces exerted at the joint. However, extended-chord-bearing joints exhibit stress concentrations on the connector plates necessitating special consideration in the design (refer to Figure 6).

- Steel Stress in Shear and Tension on the Connector Plate (8.6) – This check verifies that the connector plate possesses adequate metal shear and tensile strength to withstand the loads present in the extended-chord-bearing joint (refer to Figure 5 and 7).

- Deflection (7.6.2.3) - The truss is also evaluated to prevent undesirable deflection in the extended chord region. Even if the joint design satisfies all other strength checks, localized deflection at the joint may render it unsuitable for use. Therefore, the design check imposes limitations on deflection, including that due to the extended chord.

By considering all these failure modes in TPI 1-2022, the maximum allowable reactions for extended-chord-bearing trusses can be reliably determined by the truss designer for a wider range of configurations.

Conclusion

Periodically updating and enhancing the TPI 1 standard is crucial to capitalizing on the inherent benefits of metal plate-connected wood trusses. With the constant advancements in technology and the availability of more precise analysis and testing methods, TPI, SBCA, and their technical committees are committed to further improving the standard in future editions. The collective goal is to maintain, and even expand, the reputation of manufactured wood trusses in the market as an exceptional choice for structural framing.

The changes contained in TPI 1-2022 related to top chord-bearing trusses should make a very real impact on their value and attractiveness to builders and building designers over the coming years.

This article is the result of a collaboration between the members of the Truss Plate Institute’s Technical Advisory Committee (TPITAC) and SBCA. It is part of a technical article series driven by TPITAC members that seeks to address pertinent engineering topics and provide design best practices.