Web Wars

Fighting Force with Smart Design

BCMC 2025 Education Session: Web Wars: Fighting Force with Smart Design

Speakers: Howard Gauger, CCA/R&D Thiel; Jay Jones, P.E., Truss Plate Institute, Inc.; Ed Robbins, P.E., P.E. Robbins

In the world of structural engineering and truss design, the battle for safety and efficiency is often fought in the details. The Web Wars education session at this past BCMC 2025, delivered by Howard Gauger with R&D Thiel, Jay Jones, P.E. with Truss Plate Institute, and Ed Robbins, P.E. with Phillip E. Robbins Engineering, dove into the critical topic of permanent web bracing for trusses and the new provisions pertaining to permanent bracing that are included in BCSI-2025. The presentation highlighted the important need for permanent bracing, implications of the revised recommendations, and smart design solutions that can simplify construction and improve safety.

Understanding the Role of Web Bracing

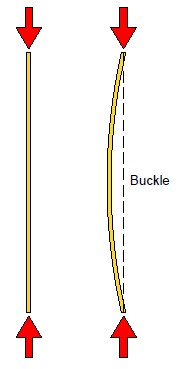

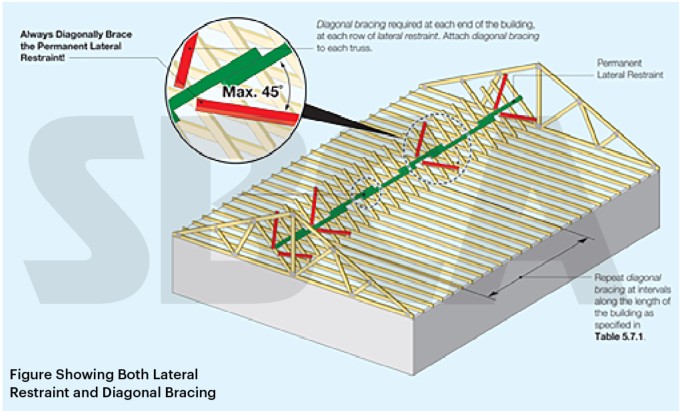

At the heart of the presentation was the importance of web bracing, specifically permanent web member lateral restraint and diagonal bracing, in maintaining the structural integrity of trusses. Truss webs – the internal members connecting the top and bottom chords – can experience either tension or compression depending on the load and design. While tension members are generally stable regardless of length, compression members are prone to buckling, especially when they are long and slender.

To combat this, engineers use lateral restraint members to reduce the effective buckling length of compression webs. However, lateral restraint members alone are not enough. They must be paired with diagonal bracing to resist the cumulative lateral forces that build up along the restraint line. Without diagonal bracing, lateral restraint members are ineffective. This can lead to potential in-service failures such as sagging roofs or even structural collapse under heavy loads like snow.

The presenters emphasized that buckling restraint forces, though small (typically 2% of the compression force), accumulate along the lateral restraint. When the compression loads in the web members are high, this accumulated force that must be properly anchored then becomes high.

The presenters emphasized that buckling restraint forces, though small (typically 2% of the compression force), accumulate along the lateral restraint. When the compression loads in the web members are high, this accumulated force that must be properly anchored then becomes high.

High-Force Webs and the Need for Smart Design

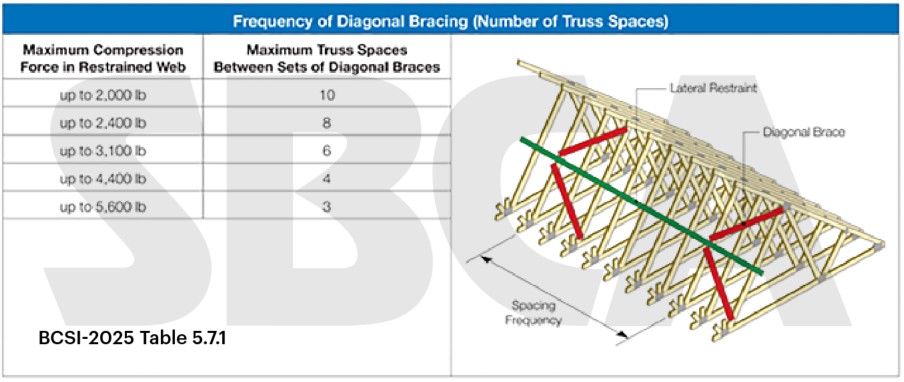

A key focus of the session was on how to identify and manage “high-force” compression webs, defined as those experiencing more than 2,000 pounds of compression force. BSCI-2025 recommends closer spacing of the diagonal bracing for these members to keep the cumulative force in the lateral restraint and diagonal bracing system within the capacity of the connections in the system. As the compression force in the member increases, the recommended spacing frequency of the diagonal members decreases. This is shown in Table 5.7.1 of BCSI-2025 and in the B3 Summary Sheet.

The presentation walked through how to identify high compression force webs using the truss design drawings (TDDs) and determine appropriate bracing intervals. Examples of how to do this using truss design drawings from the different truss design software manufacturers were provided.

The presentation walked through how to identify high compression force webs using the truss design drawings (TDDs) and determine appropriate bracing intervals. Examples of how to do this using truss design drawings from the different truss design software manufacturers were provided.

Communication and Responsibility

One of the most pressing issues raised during the presentation was who is responsible for ensuring that framers understand and implement the new diagonal brace spacing requirements. Truss design drawings currently identify required lateral restraint locations, but do not identify high compression force web members or diagonal brace spacing requirements. The session offered that until high compression force webs are clearly flagged on the truss design drawings, component manufacturers are encouraged to take proactive steps such as marking plans, holding preconstruction meetings, or adding site notes to communicate diagonal bracing needs. Clear communication is not just a best practice; it’s paramount.

Smart Design Strategies

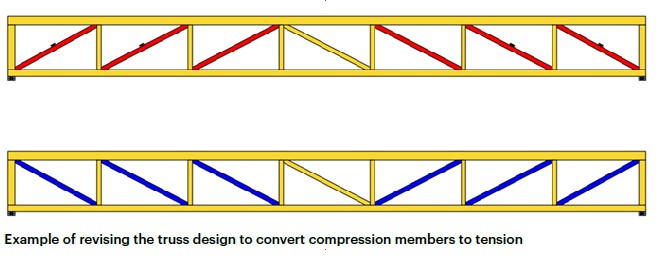

The presentation underscored that constructability should be a guiding principle in truss design. To reduce the complexity and potential additional cost associated with reduced diagonal brace spacing, the presenters advocate for smart truss designs. Their suggestions included:

- Increase the web grade or size to reduce or eliminate lateral restraint needs.

- Use “T” or “I” reinforcement instead of lateral restraint and diagonal bracing. These options are provided in BCSI-2025 Table 5.7.2. and in the B3 Summary Sheet.

- Revise the truss design and convert compression members to tension members.

These strategies aim to minimize lumber use, enhance safety, and speed up installation, ultimately leading to more cost-effective and reliable construction.

Final Takeaway

Final Takeaway

The session concluded with a powerful reminder: the cheapest truss isn’t always the most economical to install. Over-braced or poorly communicated designs can lead to wasted materials, delays, and safety risks. By prioritizing simplicity, collaboration with engineers and framers, and clear communication, the industry can move toward more buildable, efficient, and safer truss systems.

For additional information, refer to the new document, Bracing Requirements for High Compression Force Web Members (CG No. 2502), available for download from SBCA’s Knowledge Center (https://kcenter.sbcacomponents.com/). This report covers the new web member permanent diagonal bracing recommendations included in BCSI-2025 and discussed during the presentation. Examples determining the diagonal brace spacing requirements using truss design drawings from various software manufacturers are included to assist the user in understanding how to implement the updated recommendations.