Look Before You Buy

“If there’s one thing I’ve learned well over the past decade it’s that there is a lot of work to be done before you choose how to automate any part of your production process,” says Barry Dixon, owner of TrueHouse, Inc. “There are a lot of boxes to check and a lot of numbers you need to collect and review before even looking at what’s out there.”

BCMC Session: Assessing Automation More Accurately

Speakers:

Barry Dixon

TrueHouse Inc.

BJ Louws,

Louws Truss Inc.

sbcacomponents.com/bcmc2021-sessions

BJ Louws, owner of Louws Truss Inc., agrees, “Automation is not a silver bullet and it can’t happen in a vacuum. Before you make a significant investment into a piece of machinery you need to know exactly what impact it will have on your entire process.” To that end, Barry and BJ stress that every component manufacturer (CM) thinking about automation should start by being very clear about their goals. “If you want to increase your production throughput by 25 percent, that’s great, but you need to have some frank internal discussion on how you want to accomplish that,” says Barry.

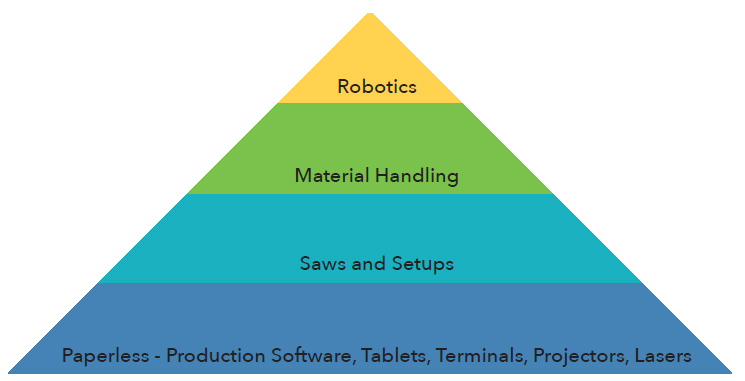

Automation can be implemented in many ways. Starting at the bottom of this pyramid and working up can be an effective strategy to avoid costly over-investment.

“The key here is if a new saw is going to increase throughput by 20 percent, what does that do to your design department?” asks BJ. “Can your sales team keep up and supply the order volume you now need to consistently hit? Can your material handling and delivery teams

manage the new level of outflow?”

Both point out that automation can cause significant disruption so it’s vitally important to get the input and buy in from your sales, production, management, and maintenance teams. BJ adds, “you also have to make sure your IT infrastructure is set up to handle the new equipment and your IT team is trained to support any new advanced systems.”

One of the biggest problems they identify is there isn’t currently a common language when talking about equipment. “You need to know what your key performance indicators (KPIs) are and make sure your teams and the equipment vendors are talking the same language,” says Barry. “If they’re promising ‘X’ but your team really wants ‘Y’, you’re going to have some major disappointment once that equipment is installed.”

Finally, BJ suggests that a CM should model their whole system prior to purchase and understand the impact it will also have on all their financials. “I think most people think clearly about the upfront investment costs and debt they take on with an equipment purchase, but there are several other things to consider,” says BJ. “What happens to wages when you shift from manual labor to more high-tech support labor? How much more lumber and plates do I need to have in stock to cover the increased capacity? Do I need to buy more trucks and hire more drivers? These are just a few examples of all the things you should evaluate and decide on prior to making a purchase.”