BCSI Guidance for Ensuring Safe Truss Erection

Originally Published by: SBCA Magazine — August 29, 2023

SBCA appreciates your input; please email us if you have any comments or corrections to this article.

The Importance of Temporary Restraint/Bracing During Truss Installation

Truss erection is a crucial phase in construction projects, facilitating the creation of structurally sound buildings. However, it's essential to recognize the inherent danger associated with this process. To mitigate risks and ensure safety, meticulous planning and communication between the contractor, crane operator, and installation crew are paramount. This article explains key considerations and safety measures that should be observed during truss assembly.

Safety First: Planning and Communication

Before commencing any truss erection, it's extremely helpful to hold a meeting involving all onsite personnel involved in lifting, installing, and restraining trusses. This meeting should encompass a review of essential documents, including construction documents (CDs) (architectural and structural plans), truss submittal package (truss design drawings and truss placement diagrams), BCSI resources, erection and installation plans, site-specific conditions, and OSHA jobsite lifting and fall protection requirements.

Regular safety reminders for the installation crew, fastening multi-ply trusses together before lifting, and thorough inspections for truss damage are recommended. It's crucial to understand that lateral restraint must always be paired with diagonal bracing for optimal rigidity and safety.

Risk and Consequences

Disregarding safety recommendations for handling, installing, restraining, and bracing trusses constitutes a primary cause of accidents during the erection process. Ignoring unsafe conditions or actions significantly elevates the likelihood of accidents leading to property damage, severe injuries, or even fatalities.

Triangulation and Bracing: Ensuring Structural Integrity

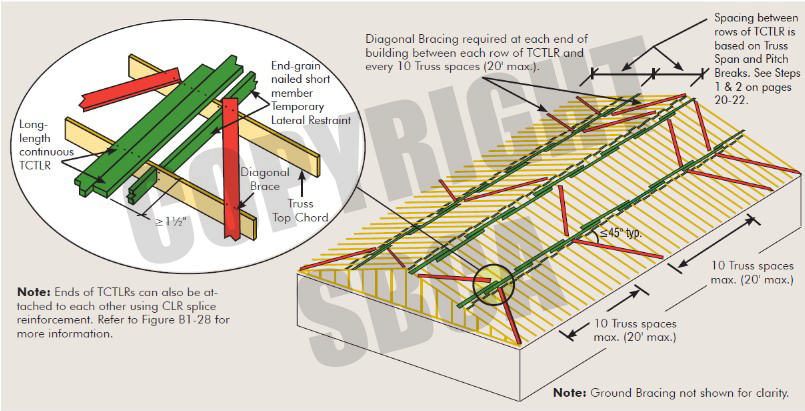

A crucial aspect of proper installation is implementing triangulation within and between the different planes of the truss, such as the top chord, bottom chord, and web. All lateral restraints must be adequately braced. This is because lateral restraint alone isn't sufficient to counteract buckling forces within its attached members. Diagonal bracing within the same plane or anchoring the lateral restraint to a lateral force resisting member, like a shear wall, provides essential rigidity for safe installation.

The Vital Role of Diagonal Bracing

A resounding directive echoes through the guidelines: never neglect the installation of diagonal bracing. In many ways, diagonal bracing is an essential safety measure.

Contractor Responsibilities

Contractors must familiarize themselves with general bracing concepts and acknowledge that the provided recommendations aren't intended to supersede the Building Designer's specifications. The Contractor's duty encompasses both safe truss lifting and proper installation. Each project's unique site conditions can impact the erection process. Therefore, all crew members, including the crane operator, must comprehend the installation plan, lateral restraint, and diagonal bracing requirements to guarantee a secure, efficient, and accident-free jobsite.

Pre-Installation Checks: Contractor's Responsibility

Prior to initiating the install process, several essential checks lie in the Contractor's domain:

-

Ensuring availability of complete building designer-approved CDs on-site.

-

Verifying the building's correct size and dimensions, rectifying any disparities prior to truss installation.

-

Confirming the proper plumbness and bracing of all load-bearing supports to prevent hazardous collapses during erection.

-

Accurate installation of bearing supports at designated locations shown on CDs.

-

Validating the level elevation of bearing supports to avoid truss unevenness.

-

Confirming straightness and parallel alignment of bearing supports.

-

Verifying truss dimensions and condition upon arrival to prevent installation delays.

-

Ensuring availability and accessibility of all required materials, hangers, angle clips, and restraints/bracing components.

-

Maintaining a clean and safe jobsite to avert trips and falls during truss installation.

-

Deciding appropriate ground bracing techniques, considering site terrain and building configuration.

-

Selecting the appropriate bracing scheme for hip style roofs, reducing the need for ground bracing.

Truss erection demands meticulous planning, adherence to safety guidelines, and comprehensive communication among all stakeholders. The construction industry's adherence to these principles guarantees not only the successful completion of projects but, more importantly, the safety and well-being of all personnel involved in truss installation. Every step taken to ensure proper truss installation is a stride towards safer and more reliable structures.